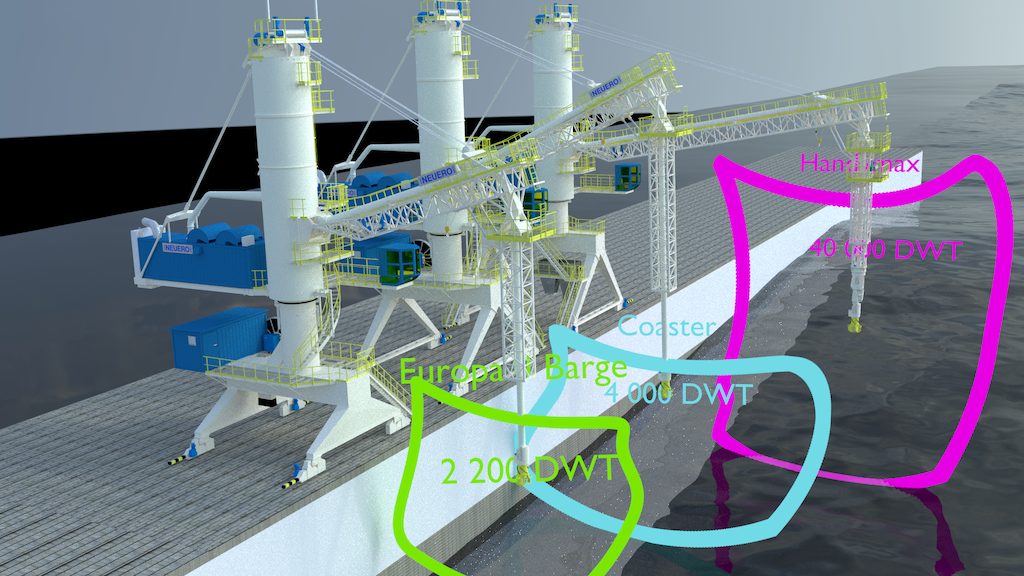

Flexiport for heavy flowing products

Can be used in particular for the unloading of bulk materials from the food sector (soy flour, gluten, fishmeal, feed pellets, etc.) as well as for products from the power plant sector such as biomass.

Unloading capacity up to 600 t/h related to wheat at 0.75 t/m3

- Special milling head to loosen up the product

- Power supply via external feed-in or diesel generators

- Discharge of ship sizes Bargen to Panamax with conveyors for loading on-site conveyors, trucks or railway wagons

- Low energy consumption

- Easy operation by extensive automatic operation

- Low dust and noise emissions

- Taking into account ATEX guidelines

- Good accessibility with low maintenance

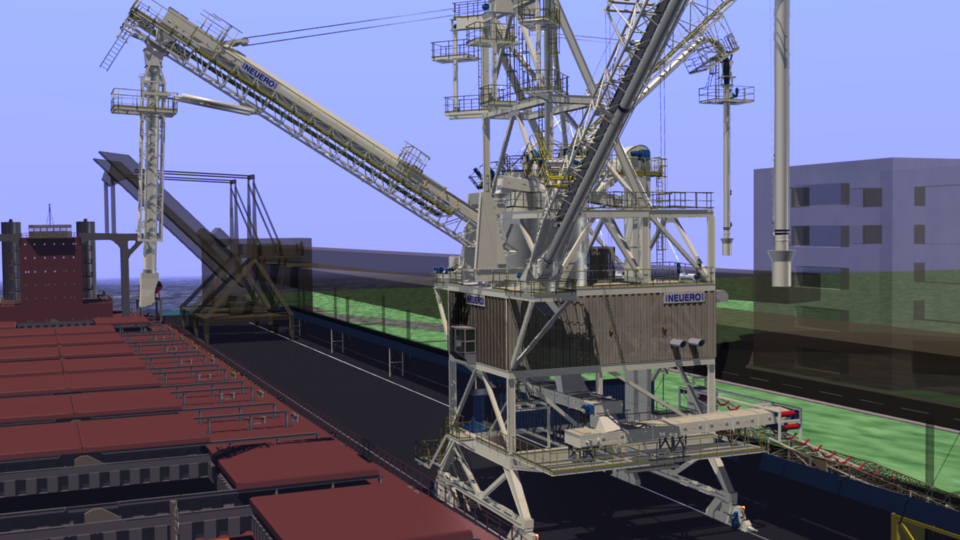

Tower for alumina and petroleum coke

NEUERO Tower is used primarily in the aluminium industry or in large grain terminals.

- Unloading capacity up to 1,500 t/h based on wheat at 0.75 t/m3 or up to 1,000 t/h based on alumina at 1.00 t/m3

- stationary or on rails

- auxiliary winch for up to 15 t

- Power supply via external feed-in

- Unloading of ship size up to Cape Size

- With conveyor facilities to support building conveyors, trucks or railway cars

- Easy operation by extensive automatic operation

- Low dust and noise emissions

- Taking into account ATEX guidelines

- Good accessibility of all facilities